Long Distance Pipe High Pressure Forged Steel Ball Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

product drawing

Long distance pipe high pressure forged steel ball valves

Product features

This ball valve series is based on the needs of customers, in order to meet the high-sulfide cracking application requirements of the sulfide environments. The design, material selection, manufacturing, testing, surface treatment and painting are carried out in accordance with the United States Corrosion Engineers NACE standards strictly.

The material selection of This ball valve series is widely, and the inside materials are using the nickel plated 316 material, the sealing ring uses a special polymer material. So that the valve is anti-corrosion, has strong anti-curing ability, fire prevention, anti-static, good sealing performance. The applicable pressure and temperature are also widely, and it has the full diameter and shrink diameter, can be zquipped with a variety of drive devices. It is the ideal choice for the chemical industry, petroleum refining, natural gas exploitation and transportation system.

Main function

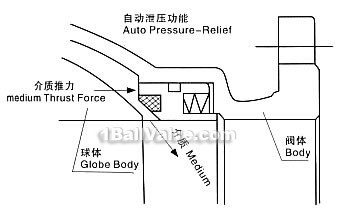

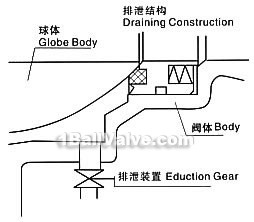

The unusual pressure rising of the stagnant medium in the middle cavity due to temperature changes, the medium pressure promotes seat out of the ball, to achieve the effect of automatic pressure relief, and after the pressure relief, the seat resets automatically.

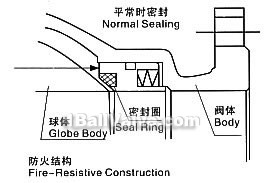

In addition to general sealing, the seat sets a sealing structure particularly, which plays a role of emergency protection when the leak happens due to the damage of the sealing ring.

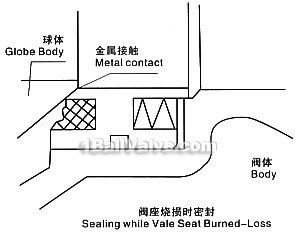

When the seat sealing ring is burned or softened by fire or abnormal temperature, the valve operation is still reliable, meanwhile the ball and the seat forms the formation of metal on metal, to achieve a temporary sealing effect, preventing further expansion of the fire, and it is in line with AP16FA requirements.

The seat seals when burned

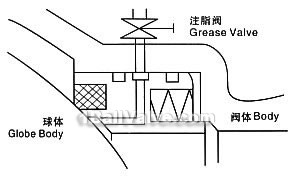

Unscrewing the exclusion device, you can check whether the seat leaks, and also can discharge residual materials in the cavity to reduce the medium unilateral pollution to the valve. In the working condition, when the valve is full open or closed, you can replace the stem packing box.

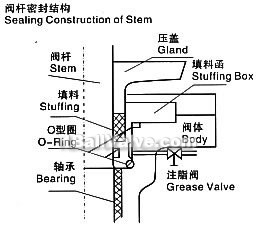

Stem sealing adopts PTFE packing and O-ring double sealing, especially for gas medium. Stem movable part uses high-quality SF self-lubricating bearings, so that the friction coefficient is smaller, and reduces the operating torque