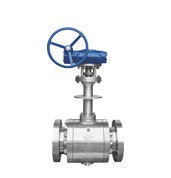

DQ347H Cryogenic Ball Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

Overview

The DQ347H low-temperature ball valve is specifically designed for ultra-low temperature medium control systems such as liquefied natural gas, liquid nitrogen, liquid oxygen, and liquid hydrocarbons, with a temperature range applicable down to -196°C. Featuring a top-mounted design and full bore flow path, the valve ensures low flow resistance and convenient online maintenance. Its opening and closing mechanism is achieved by rotating the ball 90 degrees, enabling swift and reliable operation. Both the valve body and critical components are made of austenitic stainless steel and undergo cryogenic treatment, effectively preventing material brittleness and ensuring sealing integrity and structural safety under extreme low-temperature conditions. It serves as an ideal shut-off device for key systems in liquefied gas storage and transportation, air separation, and cryogenic chemical processes.

product drawing

DQ347H Cryogenic Ball Valve

Features

1. Cryogenic Material Guarantee: The main body is made of austenitic stainless steel treated with cryogenic processing, featuring excellent low-temperature toughness to completely eliminate the risk of brittle failure between the valve body and the ball at cryogenic temperatures.

2. Long-term low-temperature sealing: Utilizes specially formulated reinforced polytetrafluoroethylene (PTFE) or metal sealing rings, combined with an elastic loading design, to automatically compensate for severe temperature fluctuations and ensure bidirectional zero leakage.

3. Anti-blowout safety design: The valve stem adopts an inverted sealing stepped structure, combined with an anti-static device, effectively preventing stem ejection even under abnormal pressure, ensuring high safety.

4. Easy and reliable operation: Equipped with built-in low-temperature lubrication bearings to significantly reduce operational torque; the extended valve cover design effectively isolates cold sources, protecting the packing and actuator while ensuring flexible valve opening and closing.

5. Fireproofing and Versatility: Compliant with API 607 fireproof standards, forming an auxiliary metal seal in case of soft seal failure; supports manual, gear, pneumatic, and electric drive methods, meeting automation control requirements.

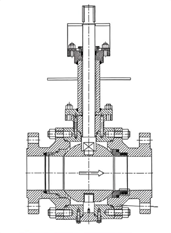

Structure

DQ347H Cryogenic Ball Valve structural diagram

| NO. | Name | Material |

|---|---|---|

| 1 | Body | 304, 316, LCB |

| 2 | Ball | 304, 316, LCB |

| 3 | Sealing Ring | PTFE |

| 4 | Packing | PTFE + O Ring |

| 5 | Stem | 304, 316, LCB |

Technical parameter

| Item | Value | Unit |

|---|---|---|

| Nominal Pressure | 1.0/1.6/4/6.4/10/15 | MPa |

| Shell Test Pressure | 1.5/2.4/6/9.6/15/22.5 | MPa |

| Seal Test Pressure | 1.1/1.76/4.4/7.04/11/16.5 | MPa |

| Suitable Temperature | -196~-29 | ℃ |

The materials of main parts

| Type | Size | Nominal Size NPS/in | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | ||

| DQ347H-CL150 DQ347H-CL150P DQ347H-CL150R |

d1 | 100 | 150 | 201 | 252 | 303 | 334 | ||

| L | 229 | 394 | 457 | 533 | 610 | 686 | |||

| D | 230 | 280 | 345 | 405 | 485 | 535 | |||

| D1 | 190.5 | 241.3 | 298.5 | 362 | 431.8 | 476.3 | |||

| D2 | — | 157 | 216 | 270 | 323.8 | 381 | 412.8 | ||

| DQ347H-CL300 DQ347H-CL300P |

d1 | 150 | 201 | 252 | 303 | 334 | 385 | ||

| L | — | 403 | 502 | 568 | 648 | 762 | |||