Q347Y Turbine Fixed Ball Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

Overview

Q347Y turbine fixed ball valve is a fixed ball valve driven by a turbine transmission mechanism. Its sphere is fixed and supported by upper and lower rotating shafts, and does not produce floating displacement under high pressure. The valve seat usually adopts a metal hard seal or composite seal structure. The valve achieves high torque output through turbine gearbox deceleration transmission, making opening and closing operations effortless and precise. This design is suitable for high-pressure, large-diameter, and frequently operated pipeline systems in fields such as petroleum, natural gas, chemical, and power stations. It can reliably cut off and control water, steam, oil, and corrosive media, especially in situations where power actuators cannot be equipped.

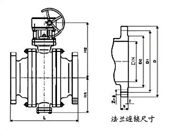

product drawing

Q347Y Turbine Fixed Ball Valve

Features

1. Turbo transmission is labor-saving and precise: using a turbo worm gear reduction mechanism, it has a large output torque, easy operation, smooth transmission, and can achieve precise control and self-locking of valve opening and closing positions.

2. Fixed ball structure resistant to high pressure: The ball is fixed by bearings, with low rotational friction. The valve seat is not easily overloaded or deformed under medium pressure, ensuring that the valve can still open and close flexibly and maintain long-term sealing under high pressure differential conditions.

3. Double sealing and fire safety: A spring preloaded valve seat design is usually used to achieve bidirectional sealing. The sealing pair can be in the form of metal to metal or soft hard composite, and comply with fire safety standards.

4. Low flow resistance and high flow capacity: The full bore design brings minimal fluid resistance, making it suitable for long-term fully open operation of conveying pipelines and reducing energy consumption. The valve stem seal is reliable, and the anti blowing design has high safety.

5. Strong adaptability and easy maintenance: suitable for manual, semi-automatic or as a backup drive device. Partial structure supports online maintenance and valve seat sealing grease injection, extending service life and reducing maintenance costs.

Structure

Q347Y Turbine Fixed Ball Valve structural diagram

| NO. | Name | Material |

|---|---|---|

| 1 | Body | Carbon Steel, Stainless Steel |

| 2 | Ball | Stainless Steel |

| 3 | Sealing Ring | Rubber |

| 4 | Packing | PTFE |

| 5 | Stem | 2Cr13, Stainless Steel |

Technical parameter

| Item | Value | Unit |

|---|---|---|

| Nominal Pressure | 150/300/600 | MPa |

| Shell Test Pressure | 3/7.6/15 | MPa |

| Seal Test Pressure | 2.2/5.6/11 | MPa |

| Suitable Temperature | 425 | ℃ |

The materials of main parts

| Nominal Diameter | L | D | D1 | D2 | b | Z-d | H | H1 | D0 |

|---|---|---|---|---|---|---|---|---|---|

| 50 | 178 | 160 | 125 | 100 | 16 | 4-18 | 160 | 85 | - |

| 65 | 191 | 180 | 145 | 120 | 18 | 4-18 | 170 | 95 | - |

| 80 | 206 | 195 | 160 | 135 | 20 | 8-18 | 200 | 110 | - |

| 100 | 229 | 215 | 180 | 155 | 20 | 8-18 | 210 | 120 | - |

| 125 | 356 | 245 | 210 | 185 | 22 | 8-18 | 350 | 215 | - |

| 150 | 394 | 280 | 240 | 210 | 24 | 8-23 | 530 | 190 | - |

| 200 | 457 | 335 | 295 | 265 | 26 | 12-23 | 575 | 230 | 600 |

| 250 | 533 | 405 | 355 | 320 | 30 | 12-25 | 585 | 260 | 600 |

| 300 | 610 | 460 | 410 | 375 | 30 | 12-25 | 730 | 300 | 600 |

| 350 | 686 | 520 | 470 | 435 | 34 | 16-25 | 860 | 350 | 800 |

| 400 | 762 | 580 | 525 | 485 | 36 | 16-30 | 935 | 395 | 800 |

| 450 | 864 | 640 | 585 | 545 | 40 | 20-30 | 975 | 440 | 800 |

| 500 | 912 | 705 | 650 | 608 | 44 | 20-34 | 1060 | 485 | 800 |