Q41F API Ball Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

Overview

Q41F API Ball Valve is a flange connected ball valve designed and manufactured in accordance with American standards such as ASME B16.34. It adopts a floating ball or fixed ball structure and can be quickly opened and closed by rotating the ball 90 degrees. Valve bodies are typically made of ASTM standard materials such as A216 WCB cast steel, CF8 stainless steel, etc., with pressure ratings ranging from Class 150 to Class 600. The valve adopts PTFE reinforced sealing or metal hard sealing to ensure reliable cut-off and connection control of water, steam, oil and corrosive media in medium and high pressure pipeline systems in industries such as petroleum, natural gas, chemical, and power.

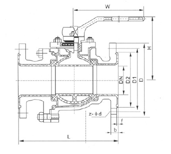

product drawing

Q41F API Ball Valve

Features

1. Standard compliant design: Strictly follow American standards such as ASME and API, and be compatible with internationally recognized standards in terms of pressure rating, structural length, flange size, and material requirements, ensuring interchangeability and global project adaptability.

2. High performance sealing: The combination of precision ground spheres and reinforced PTFE or high-temperature resistant PPL valve seats forms a bi-directional seal, suitable for various working conditions, and some models support fire and anti-static design.

3. Stable connection and pressure bearing: RF or RTJ flange surface is used, combined with high-strength bolt connection, the structure is stable, able to withstand system pressure fluctuations and pipeline stress, and has high safety.

4. Low torque operation: Smooth flow channel, low friction coefficient, can achieve lightweight 90 degree opening and closing operation even under high pressure difference, and can be equipped with gearbox or pneumatic/electric actuators.

5. Easy and reliable maintenance: Most designs are top mounted or detachable connections, which facilitate online maintenance and replacement of valve seat seals, extend valve service life, and reduce operation and maintenance costs.

Structure

Q41F API Ball Valve structural diagram

| NO. | Name | Material |

|---|---|---|

| 1 | Body | Carbon Steel, Stainless Steel |

| 2 | Ball | Stainless Steel |

| 3 | Sealing Ring | PTFE, RPP |

| 4 | Packing | PTFE |

| 5 | Stem | Stainless Steel |

Technical parameter

| Item | Value | Unit |

|---|---|---|

| Nominal Pressure | 1.6/2.5/4/6.4 | MPa |

| Shell Test Pressure | 2.4/3.75/6/9.6 | MPa |

| Seal Test Pressure | 1.76/2.75/4.4/7.04 | MPa |

| Suitable Temperature | ≤350 | ℃ |

The materials of main parts

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 250 | 280 | 320 | 360 | 400 |

| H | 59 | 63 | 75 | 85 | 95 | 107 | 140 | 152 | 178 | 252 | 272 | 342 |

| W | 130 | 130 | 160 | 180 | 230 | 230 | 400 | 400 | 650 | 1050 | 1050 | 1410 |

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 250 | 320 | 400 | 400 | 550 |

| H | 59 | 63 | 75 | 97 | 107 | 142 | 152 | 178 | 252 | 272 | 342 | 345 |

| W | 130 | 130 | 160 | 230 | 230 | 400 | 400 | 700 | 1100 | 1100 | 1500 | 1500 |

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 130 | 140 | 150 | 180 | 200 | 220 | 250 | 280 | 320 | 400 | 400 | 550 |

| H | 59 | 63 | 75 | 97 | 107 | 142 | 152 | 178 | 252 | 272 | 342 | 345 |

| W | 130 | 130 | 160 | 230 | 230 | 400 | 400 | 700 | 1000 | 1100 | 1500 | 1800 |

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 165 | 190 | 216 | 229 | 241 | 292 | 330 | 356 | 432 | 408 | 559 | 660 |

| H | 59 | 63 | 75 | 97 | 107 | 142 | 152 | 178 | 252 | 272 | 305 | 398 |

| W | 130 | 130 | 160 | 230 | 230 | 400 | 400 | 700 | 1000 | 1100 | 1500 | 1800 |