Q41Y 3PCS Forged Steel Ball Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

Overview

Q41Y three piece forged steel ball valve is a high-pressure resistant ball valve composed of a forged steel valve body and three bolted connections. The valve body and components are usually made of forged steel materials such as A105, F304/F316, which obtain a dense structure through forging processes and have higher mechanical strength and pressure bearing capacity. The core seal adopts a three-dimensional hard sealing structure with spherical surface welding or spraying hard alloy (such as Stellite alloy), and the valve seat is made of metal or reinforced graphite, which can maintain sealing stability under high temperature, high pressure and frequent operation. This valve is designed to comply with high standard specifications such as API and ASME, with a nominal pressure of up to Class 1500. It is widely used in key pipelines such as petrochemicals, oil and gas extraction, power plants, and refining, and is suitable for reliable cutoff of harsh working conditions such as water, steam, oil products, and natural gas.

product drawing

Q41Y 3PCS Forged Steel Ball Valve

Features

1. Excellent high pressure and high temperature performance: The overall forged steel valve body has a dense structure, no casting defects, excellent mechanical properties, and can reliably withstand harsh working conditions such as high pressure, high temperature, and frequent pressure fluctuations, with high safety.

2. Hard metal sealing is wear-resistant and durable: The ball and valve seat are sealed with hard alloy or metal reinforced PTFE/graphite, which is resistant to erosion and high temperature, suitable for high temperature and media with small particles, and has a long service life.

3. Convenient maintenance of the three piece structure: The valve body is composed of a middle valve body and two end connecting bodies that are fastened by bolts. The middle chamber can be easily disassembled without completely removing it from the pipeline, making it easy to quickly inspect, clean or replace internal sealing components, greatly reducing maintenance costs and time.

4. Reliable connection and strong adaptability: The standard configuration is flange connection, and welding ends can also be provided according to demand. Compact and sturdy structure, some models support fully welded valve body design, suitable for underground or environments with extremely high leakage requirements.

5. Fireproof and bidirectional sealing design: usually in compliance with API 607/API 6FA fire testing standards, it can still ensure a certain degree of sealing through metal assisted sealing even when the soft seal fails. Most designs are bi-directional seals that are not restricted by the flow direction of the medium.

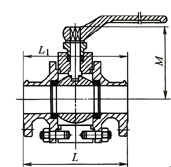

Structure

Q41Y 3PCS Forged Steel Ball Valve structural diagram

| NO. | Name | Material |

|---|---|---|

| 1 | Body | Carbon Steel, Stainless Steel |

| 2 | Ball | Stainless Steel |

| 3 | Sealing Ring | Spray Welding, Overlay Welding, Hard Alloy |

| 4 | Packing | Flexible Graphite |

| 5 | Stem | 2Cr13, Stainless Steel |

Technical parameter

| Item | Value | Unit |

|---|---|---|

| Nominal Pressure | 1.6/4/10 | MPa |

| Shell Test Pressure | 2.4/6/15 | MPa |

| Seal Test Pressure | 1.7/6.6/16.5 | MPa |

| Suitable Temperature | 400 | ℃ |

The materials of main parts

| PN | SIZE | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16、20 | L | 140 | 152 | 165 | 178 | 190.5 | 216 | 241 | 283 | 305 | 381 | 457 | 521 |

| L1 | 140 | 152 | 165 | 178 | 190.5 | 216 | 241 | 283 | 305 | 381 | 457 | 521 | |

| M | 59 | 63 | 75 | 95 | 95 | 107 | 142 | 152 | 178 | 252 | 272 | 342 | |

| 40、50 | L | 140 | 152 | 165 | 178 | 190.5 | 216 | 241 | 283 | 305 | 381 | 403 | 502 |

| L1 | 140 | 152 | 165 | 178 | 190.5 | 216 | 241 | 283 | 305 | 381 | – | – | |

| M | 59 | 63 | 75 | 95 | 95 | 107 | 142 | 152 | 178 | 252 | 272 | 342 | |

| 100 | L | 165 | 190.5 | 216 | 178 | 241 | 292 | 330 | 356 | 406/432 | – | 559 | 660 |

| L1 | 165 | 190.5 | 216 | 178 | 241 | 292 | 330 | 356 | 406/432 | – | 559 | 660 | |

| M | 59 | 63 | 75 | 95 | 95 | 167 | 180 | 198 | 198 | – | – | – |