Q671F Pneumatic Wafer Ball Valve

manufacturer: Kaiweixi Valve Group Co., Ltd.

Eml: Yannie@kaiweixi.com

Tel: +86(577)67038872

Mob: +86 189 6779 6135(WeChat Same Account)

Overview

The Q671F pneumatic Wafer ball valve is an automated shut-off valve that uses a Wafer type connection and is driven by a pneumatic actuator. The valve body itself does not have a flange, and is directly Wafered between two pipe flanges with long bolts, making the structure extremely compact and lightweight. It drives the valve stem through a pneumatic actuator to rotate the ball 90 degrees, achieving rapid opening and closing. The valve seat usually uses soft sealing materials such as polytetrafluoroethylene (PTFE) to ensure reliable sealing. This valve is powered by compressed air and can be activated upon receiving control signals. It is particularly suitable for situations where space is limited, lightweight is required, and frequent automatic shut-off is required. It is widely used in chemical, pharmaceutical, food, environmental water treatment, and light industry automation production lines to remotely or programmatically control liquids, gases, and other media.

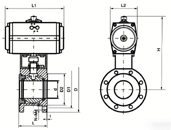

product drawing

Q671F Pneumatic Wafer Ball Valve

Features

1. Compact and lightweight structure: The Wafer type design eliminates the need for valve body flanges, resulting in a thin and lightweight overall structure, short installation length, and significant savings in pipeline space and material costs. It is particularly suitable for dense pipeline layouts.

2. Pneumatic Drive Fast and Accurate: Equipped with single/double acting pneumatic actuators, it opens and closes quickly (usually in just a few seconds), responds sensitively, facilitates automation control and remote operation, and improves system efficiency.

3. Economic efficiency and convenient installation: Compared to flange connected valves, Wafer type structures are more economical. During installation, only long bolts are needed to Wafer the pipeline flange, which is simple and fast.

4. Excellent sealing and low flow resistance: The ball and soft valve seat form a tight seal with low leakage rate. The full bore design has extremely low flow resistance and almost no impact on pipeline flow, resulting in good energy-saving effects.

5. Integration flexibility and safety reliability: It is convenient to install accessories such as solenoid valves, limit switches, locators, etc., to achieve signal feedback and adjustment functions. Usually equipped with fire-resistant, anti-static, and valve stem anti blowing design, with high safety performance.

Structure

Q671F Pneumatic Wafer Ball Valve structural diagram

| NO. | Name | Material |

|---|---|---|

| 1 | Body | Carbon Steel, Stainless Steel |

| 2 | Ball | Carbon Steel, Stainless Steel |

| 3 | Sealing Ring | PTFE |

| 4 | Packing | PTFE |

| 5 | Stem | 1Cr13, Stainless Steel |

| 6 | Position Indicator | Plastic |

Technical parameter

| Item | Value | Unit |

|---|---|---|

| Nominal Pressure | 1.6/2.5 | MPa |

| Shell Test Pressure | 2.4/3.75 | MPa |

| Seal Test Pressure | 1.76/2.75 | MPa |

| Suitable Temperature | 300 | ℃ |

The materials of main parts

| DN | d | L | L1 | L2 | H | D | D1 | D2 | f | N-d |

|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 35 | 140 | 178 | 170 | 90 | 65 | 45 | 2 | 4-M14 | - |

| 20 | 38 | 140 | 178 | 175 | 100 | 65 | 45 | 2 | 4-M14 | - |

| 25 | 42 | 160 | 214 | 181 | 110 | 75 | 55 | 2 | 4-M14 | - |

| 32 | 50 | 160 | 214 | 191 | 120 | 85 | 65 | 2 | 4-M16 | - |

| 40 | 58 | 160 | 246 | 215 | 145 | 100 | 85 | 3 | 4-M16 | - |

| 50 | 70 | 190 | 295 | 248 | 268 | 125 | 100 | 3 | 4-M16 | - |

| 65 | 85 | 210 | 295 | 285 | 284 | 180 | 145 | 3 | 4-M18 | - |

| 80 | 116 | 241 | 395 | 312 | 306 | 195 | 160 | 3 | 8-M18 | - |

| 100 | 140 | 276 | 478 | 375 | 370 | 215 | 180 | 3 | 8-M20 | - |

| 125 | 170 | 345 | 562 | 406 | 445 | 270 | 220 | 3 | 8-M24 | - |

| 150 | 210 | 376 | 574 | 428 | 500 | 300 | 240 | 3 | 8-M24 | - |